Are you working on a project that requires the use of a DC motor? Choosing the right DC motor is crucial to the success of your project. With so many options available, it can be overwhelming to determine which motor is best suited for your specific needs. In this guide, we’ll walk you through the process of selecting the perfect DC motor for your project.

Understand Your Requirements: The first step in selecting a DC motor is to clearly define your project requirements. Consider factors such as torque, speed, size, voltage, and power consumption. Understanding these requirements will help narrow down your options and ensure you choose a motor that meets your needs.

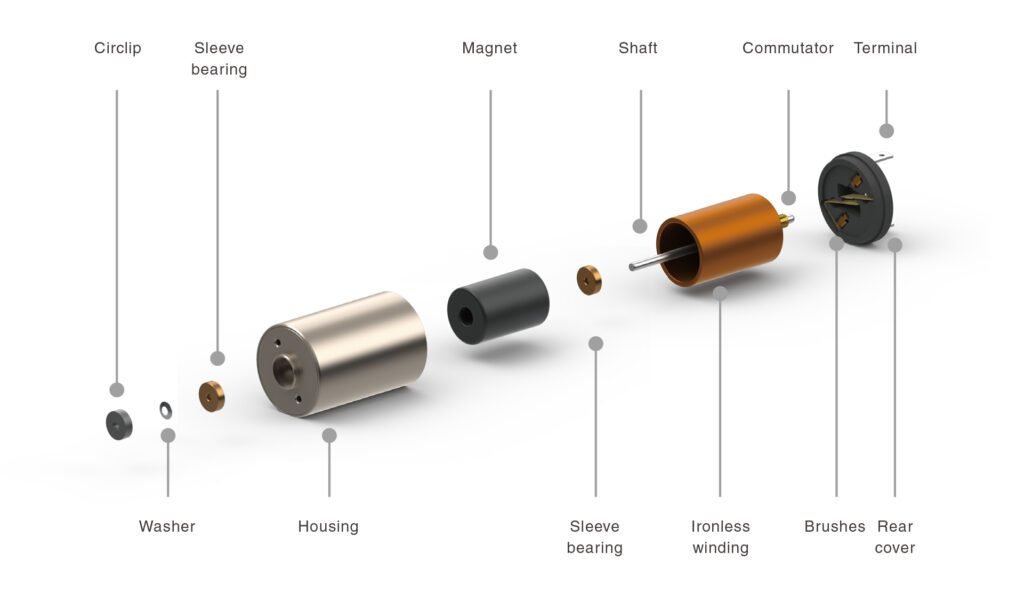

Determine the Motor Type: DC motors come in various types, including brushed DC motors, brushless DC motors, and stepper motors. Each type has its own advantages and disadvantages, so it’s essential to determine which type is best suited for your project. Brushed DC motors are simple and cost-effective but may require more maintenance. Brushless DC motors are more efficient and reliable but tend to be more expensive. Stepper motors are ideal for applications requiring precise control but may be less efficient.

Consider Size and Form Factor: The size and form factor of the motor are important considerations, especially if space is limited in your project. Be sure to choose a motor that fits within the available space while still providing the necessary performance.

Evaluate Voltage and Power Requirements: DC motors are available in a wide range of voltages and power ratings. It’s essential to select a motor that operates within the voltage range of your project and provides the required power output. Be sure to consider both the nominal voltage and the stall current of the motor.

Review Performance Characteristics: Look for motors that offer the desired performance characteristics, such as speed-torque curves, efficiency, and operating temperature range. These factors will impact the overall performance and reliability of your project.

Check for Additional Features: Depending on your project requirements, you may need a motor with specific features such as built-in encoders, gearboxes, or waterproofing. Consider whether these additional features are necessary for your application and choose a motor accordingly.

Compare Prices and Suppliers: Once you have narrowed down your options, compare prices and suppliers to find the best deal. Consider factors such as quality, reliability, and customer support when selecting a supplier.

By following these steps, you can confidently select the right DC motor for your project. Remember to carefully consider your requirements, evaluate different options, and choose a motor that provides the best combination of performance, size, and cost. With the right motor, your project will be well-positioned for success.